Installation and Maintenance Tips

Once you’ve got your ideal servo, you need to make sure it’s installed correctly and well-maintained to keep your RC airplane flying smoothly. Take a look at our handy guide to help you get your servos set up and keep them in top shape.

Step-by-Step Installation Guide

-

Gather Your Tools and Components

-

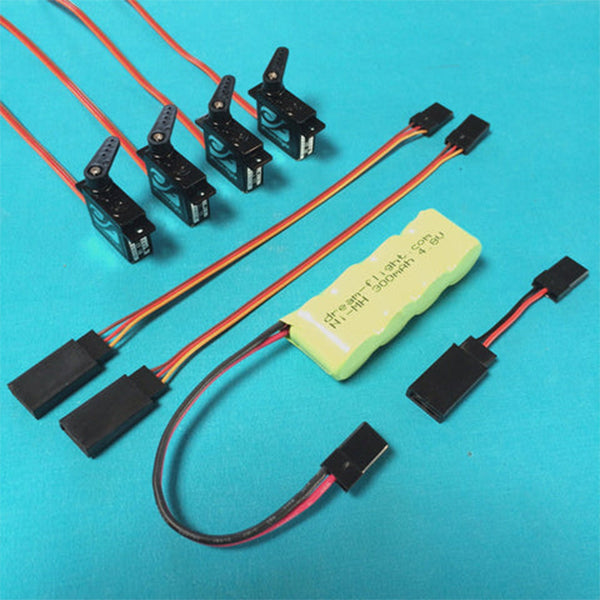

You’ll need a screwdriver, a servo tester, extension cables if necessary, and of course, your servos.

-

Check that your transmitter and receiver are ready to go and compatible with the servos you’re using.

-

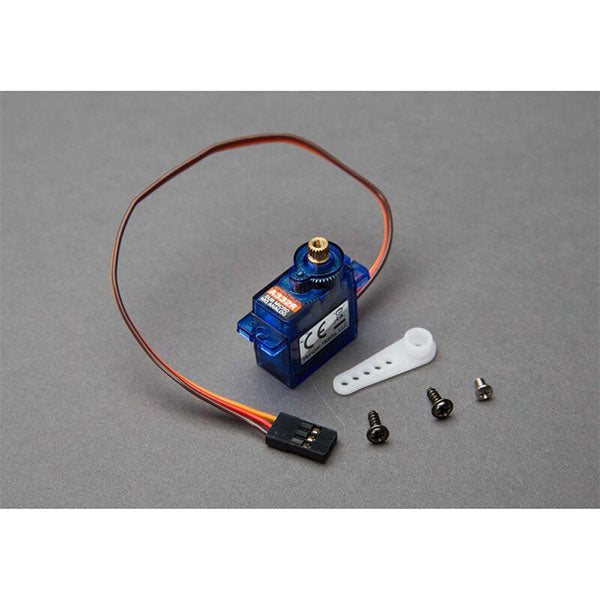

Mount the Servo

-

Place the servo in the designated spot in your RC airplane.

-

Secure it with the screws, making sure it’s snug but not too tight.

-

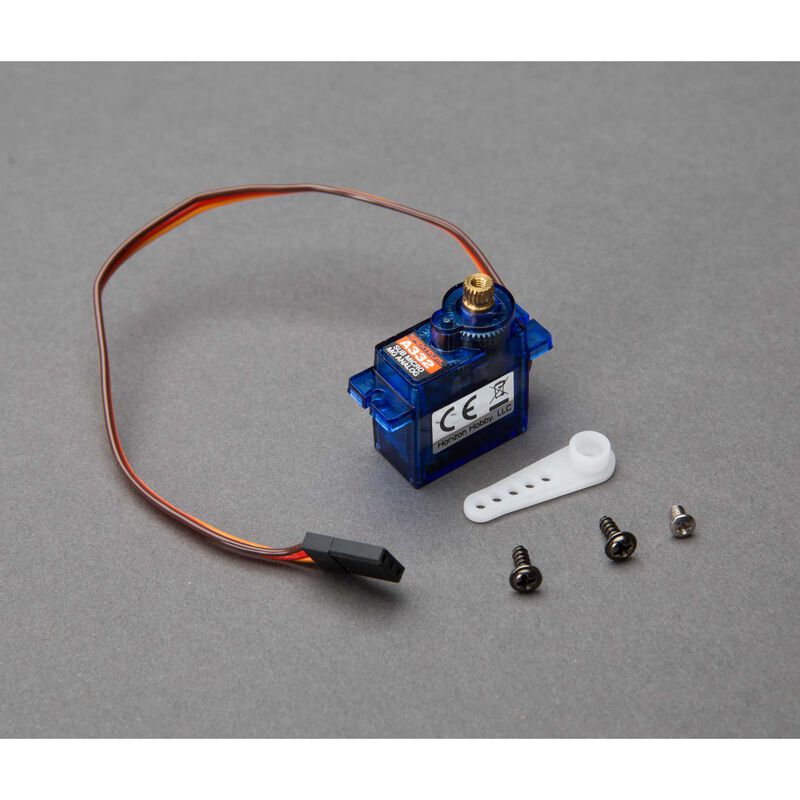

Attach the Servo Horn

-

Connect the servo horn to the output shaft.

-

Make sure the horn is centered before tightening the screw to prevent initial misalignment.

-

Set Up the Linkage

-

Connect the horn to the control surface with pushrods or linkage rods.

-

Adjust the length so the control surface is neutral when the servo is centered.

-

Power Up and Test

-

Turn on your transmitter and receiver.

-

Use a servo tester to check if it moves smoothly and responds correctly to your commands.

-

Make any necessary adjustments to the linkage for proper movement.

-

Final Checks

-

Double-check all connections to make sure nothing is loose.

-

Test the control sticks on your transmitter to ensure the control surfaces move correctly.

Maintenance Best Practices

-

Regular Inspections: Look over your servos before and after each flight for any signs of wear or damage. Make sure the horn, linkage, and screws are secure.

-

Keep It Clean: Clean your device to keep dust and debris at bay. Use a soft brush or compressed air for gentle cleaning without causing damage.

-

Lubricate: Occasionally, apply a bit of lubricant to the gears (if you can access them) to reduce wear.

-

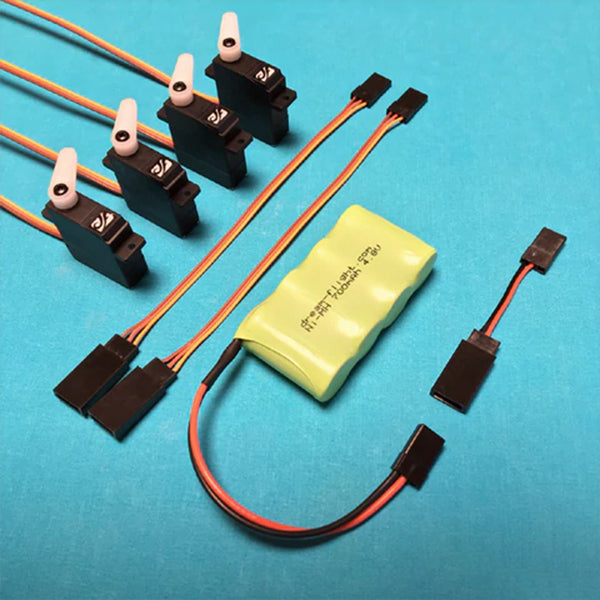

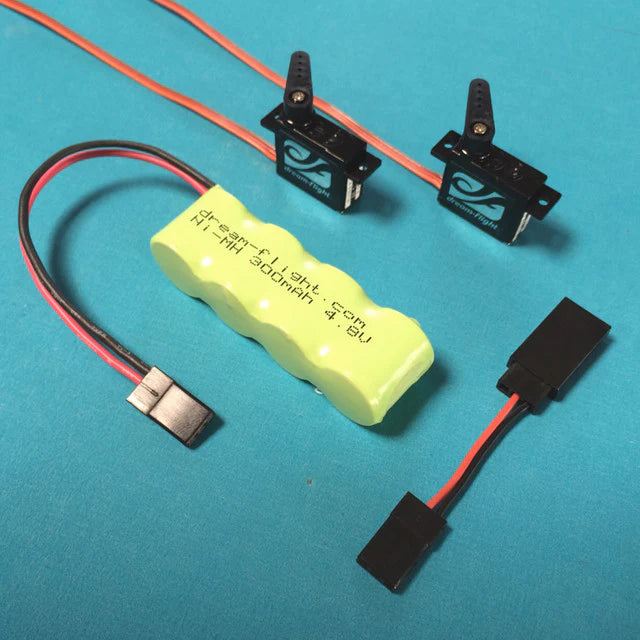

Proper Storage: Store your RC airplane in a cool, dry place to prevent moisture from damaging electronic components.

-

Battery Care: Make sure the battery is fully charged and in good condition. Avoid using damaged or low-charge batteries, as they can affect performance.

Troubleshooting Common Issues

|

Cause |

Solution |

|

|

Servo Jitter |

Electrical interference or weak signal. |

Check for loose connections, ensure good signal reception, and consider using a ferrite ring to cut down interference. |

|

No Movement |

Faulty servo, disconnected wires, or dead battery. |

Check all connections, use a servo tester, and replace the battery if needed. |

|

Erratic Movement |

Stripped or damaged gears. |

Inspect and, if necessary, replace the gears or the entire servo. |

|

Overheating |

Overloading or continuous heavy use. |

Make sure the servo isn’t overloaded and has good airflow for cooling. |

Why Choose RC Visions for Your RC Airplane Servos

At RC Visions, we're passionate about providing the best components for your RC airplane, and our selection of servos is no exception. So if you’re looking for only the best online RC store, take a look at our wide variety of high-quality devices to suit any flying style and aircraft size. We guarantee you get products that are reliable, durable, and perfect for enhancing your flight experience.